Manual Transfer Case: A Comprehensive Overview (Updated 02/18/2026)

Manual transfer cases expertly manage torque distribution, utilizing a positive displacement pump for lubrication and enabling seamless shifts between drive modes for optimal performance.

What is a Manual Transfer Case?

A manual transfer case is a vital mechanical component found in four-wheel drive (4WD) and all-wheel drive (AWD) vehicles. Unlike automatic systems, it relies on the driver to physically engage and disengage the front axle, controlling torque split. This robust system channels power from the transmission to both the front and rear axles.

The transfer case’s core function is to distribute engine torque, allowing for varied driving conditions. A positive displacement fluid pump ensures consistent lubrication, vital for smooth operation. During two-wheel drive, torque passes directly through, while 4WD engages the front driveshaft, powering the front differential and enhancing traction.

The Core Function: Torque Distribution

The primary role of a manual transfer case is precise torque distribution. It manages how much power reaches the front and rear axles, adapting to terrain and driving needs. In 2WD, all torque flows rearward, maximizing efficiency. Engaging 4WD splits the torque, providing superior traction on slippery surfaces.

This distribution is crucial for off-road capability and stability. The system, lubricated by a positive displacement pump, ensures smooth power transfer. When wheel slip occurs, the transfer case engages the front driveshaft, delivering power to the front differential, enhancing grip and control.

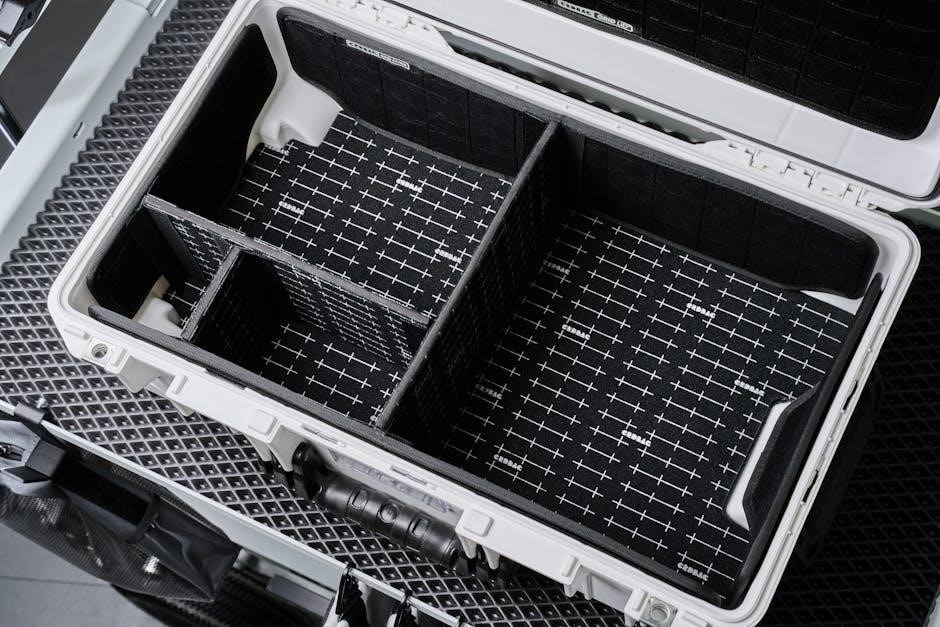

Components of a Manual Transfer Case

A manual transfer case comprises several key components working in harmony. Gears and gear ratios dictate torque multiplication and speed. Robust shift forks and rails, controlled by the driver, physically engage different gear sets. Durable chain or splined shafts transmit power between gears and to the output shafts.

Crucially, a positive displacement fluid pump ensures consistent lubrication throughout. The case itself houses these parts, protecting them from the elements. Proper function of each component is vital for reliable 4WD engagement and overall system performance.

Gears and Gear Ratios

Gears within a manual transfer case are fundamental to torque and speed manipulation. Different gear ratios provide varying levels of mechanical advantage. Lower ratios, like those used in 4L, amplify torque for challenging terrain, while higher ratios prioritize speed for normal driving conditions.

The arrangement and size of these gears directly impact the vehicle’s capability. Precision machining and durable materials are essential for withstanding the stresses of off-road use. Proper gear engagement, facilitated by the system, ensures efficient power delivery.

Shift Forks and Rails

Shift forks and rails are critical components in a manual transfer case, enabling the driver to mechanically select different drive modes – 2H, 4H, and 4L. These precisely engineered parts translate the driver’s lever movement into internal gear selection.

Durable construction is paramount, as they endure significant force during shifting. Smooth operation relies on proper lubrication and alignment. Worn or damaged forks can cause grinding noises or difficulty engaging four-wheel drive, requiring inspection and potential replacement for reliable performance.

Chain or Splined Shafts

Manual transfer cases utilize either chains or splined shafts to transmit power between the gears. Chains are common in lighter-duty applications, offering a cost-effective solution, while splined shafts provide increased strength and durability for heavier vehicles and demanding conditions.

These components must withstand substantial torsional stress. Regular inspection for wear, stretching (in chains), or damage (in splines) is crucial. Proper alignment and tension are vital for efficient power transfer and preventing premature failure, ensuring reliable four-wheel drive operation.

Types of Manual Transfer Cases

Manual transfer cases broadly fall into two categories: part-time and full-time. Part-time transfer cases allow the driver to manually engage or disengage four-wheel drive as needed, ideal for situations requiring extra traction on loose surfaces. Full-time cases, often employing viscous couplings, continuously distribute power to all wheels.

Viscous couplings automatically adjust torque distribution based on wheel slip, enhancing stability on varied terrain. Selecting the appropriate type depends on intended use and driving conditions, impacting vehicle handling and performance.

Part-Time Transfer Cases

Part-time transfer cases are designed for intermittent four-wheel drive use, offering increased traction when needed on slippery surfaces like snow, mud, or sand. Drivers manually select between two-wheel drive and four-wheel drive modes, optimizing fuel efficiency when 4WD isn’t required.

These systems typically feature a straightforward design, prioritizing durability and simplicity. Operation involves engaging power to the front driveshaft, connecting it to the front differential for enhanced grip. Avoid using on dry pavement to prevent drivetrain binding.

Full-Time Transfer Cases (Viscous Coupling)

Full-time transfer cases, often employing a viscous coupling, continuously distribute power to all four wheels, providing enhanced stability and traction on all surfaces. Unlike part-time systems, they don’t require manual engagement; the viscous coupling automatically manages torque distribution.

The viscous coupling utilizes fluid shear to transfer torque between the front and rear axles, reacting to wheel speed differences. This allows for seamless transitions and improved handling in varied conditions, though they generally offer less aggressive off-road capability.

How a Manual Transfer Case Works: The Mechanics

Manual transfer cases function by utilizing a series of gears, shift forks, and shafts to redirect torque from the transmission to both the front and rear axles. The driver selects the desired mode – 2WD, 4WD High, or 4WD Low – via a shift lever, engaging specific gear sets.

This mechanical process alters the torque split and gear reduction, providing increased traction and control. A positive displacement pump ensures consistent lubrication, while the rear output shaft receives fluid flow through dedicated holes, vital for smooth operation.

Engaging 4-Wheel Drive: Step-by-Step

To engage 4WD in a manual transfer case, ensure the vehicle is traveling on a low-traction surface. With the vehicle in neutral, carefully shift the transfer case lever into the 4WD position. This mechanically connects the front driveshaft, delivering power to the front differential and wheels.

Confirm engagement; a slight binding sensation is normal. Remember, operation in 2WD is standard, passing all torque through the case. Avoid prolonged use on dry pavement to prevent drivetrain stress and potential damage.

Understanding Transfer Case Gear Ratios

Transfer case gear ratios significantly impact vehicle performance. High range (4H) provides increased traction for challenging conditions, maintaining a reasonable speed. Conversely, low range (4L) dramatically increases torque, ideal for steep inclines or heavy loads, but limits speed.

The ratio multiplies engine torque, enhancing crawling ability. Selecting the correct range is crucial; misuse can strain the drivetrain. Understanding these ratios unlocks the full potential of your 4-wheel drive system.

High Range (2H/4H)

High range (4H) is your go-to for improved traction on slippery surfaces like snow, gravel, or wet pavement. It engages all four wheels while maintaining a standard gearing ratio, allowing for normal driving speeds with enhanced stability.

This mode distributes power to both axles, reducing wheel spin and improving control. It’s perfect for situations demanding extra grip without sacrificing on-road usability, offering a balanced approach to challenging terrain.

Low Range (4L)

Low range (4L) dramatically increases torque at the wheels, making it ideal for navigating extremely challenging terrain like steep inclines, deep mud, or rocky trails. It achieves this by significantly reducing vehicle speed while multiplying engine power.

Engaging 4L provides exceptional control and prevents stalling, allowing you to crawl over obstacles with precision. This mode is crucial when maximum power and minimal speed are required, offering unparalleled off-road capability and confidence.

Lubrication and Fluid Requirements

Proper lubrication is absolutely critical for the longevity and efficient operation of a manual transfer case. A positive displacement fluid pump ensures consistent fluid flow, cooling internal components and reducing friction.

Using the correct fluid type is paramount; consult your vehicle’s owner’s manual for specific specifications. Regular fluid checks and timely changes prevent wear and tear, safeguarding against costly repairs. Neglecting this vital maintenance can lead to premature failure and diminished performance.

Fluid Type Specifications

Selecting the correct fluid is non-negotiable for your manual transfer case’s health. Most manufacturers specify a unique Automatic Transmission Fluid (ATF) – often a specific Dexron variant – designed to withstand the high stresses and temperatures within the unit.

Avoid using universal fluids unless explicitly approved, as they may lack necessary additives. The positive displacement pump relies on fluid viscosity for optimal performance. Always verify compatibility with your vehicle’s model year and transfer case type before any fluid change.

Checking and Changing Transfer Case Fluid

Regular fluid checks are crucial; locate the fill/check plug, typically on the transfer case’s side. With the engine running in neutral, and warmed up, remove the plug and assess the fluid level – it should be even with the opening.

Changing the fluid usually involves draining the old fluid via a drain plug, replacing the gasket, and refilling with the specified ATF. Ensure proper disposal of used fluid and verify the positive displacement pump is functioning correctly post-change.

Common Problems with Manual Transfer Cases

Manual transfer cases, while robust, can experience issues. Grinding noises during shifting often indicate worn gears or synchronization problems within the case. Fluid leaks, stemming from seals or gaskets, can lead to insufficient lubrication, potentially damaging internal components and the positive displacement pump.

A frequent concern is failure to engage 4WD, possibly due to a faulty shift fork, rail, or internal linkage. Addressing these promptly prevents further damage and ensures reliable operation.

Grinding Noises During Shifting

Grinding noises when engaging or disengaging 4-wheel drive in a manual transfer case typically signal synchronization issues. Worn or damaged gears, or a lack of proper lubrication from the positive displacement pump, exacerbate this problem. The shift forks and rails may also be misaligned or damaged, preventing smooth gear engagement.

Ignoring these sounds can lead to accelerated wear and eventual failure of the transfer case’s internal components, requiring costly repairs or a complete replacement.

Fluid Leaks

Fluid leaks from a manual transfer case are a common issue, often stemming from deteriorated seals or gaskets. The positive displacement fluid pump relies on maintaining proper fluid levels for effective lubrication and operation. Leaks can lead to insufficient lubrication, causing increased friction and potential damage to gears and bearings.

Regularly inspecting the transfer case for signs of leakage is crucial. Addressing leaks promptly prevents further complications and costly repairs, ensuring optimal performance and longevity.

Failure to Engage 4WD

Failure to engage 4WD in a manual transfer case can indicate several underlying problems. A common cause involves issues with the shift forks and rails, preventing proper gear engagement. Insufficient fluid, due to leaks or low levels maintained by the positive displacement pump, can also hinder operation.

Additionally, worn or damaged chain or splined shafts may contribute to this issue. Diagnosing the root cause is essential for effective repair, restoring the vehicle’s four-wheel-drive capability.

Troubleshooting a Non-Engaging Transfer Case

Troubleshooting a non-engaging transfer case begins with verifying sufficient fluid levels, ensuring the positive displacement pump is functioning correctly. Inspect shift linkage for damage or binding, preventing full engagement. Examine the chain or splined shafts for wear or breakage, crucial for torque transfer.

Listen for unusual noises during shifting attempts, potentially indicating internal gear damage. A thorough inspection of the shift forks and rails is also vital to pinpoint the issue.

Transfer Case Maintenance Tips

Regular maintenance extends the life of your manual transfer case. Prioritize frequent fluid checks, ensuring proper levels and condition, as the positive displacement pump relies on clean fluid. Conduct visual inspections for any signs of leaks around the case and seals, addressing them promptly.

Pay attention to shifting smoothness; any grinding noises warrant immediate investigation. Following these simple steps helps prevent costly repairs and maintains optimal 4WD performance.

Regular Fluid Checks

Consistent fluid level checks are crucial for manual transfer case health. The positive displacement pump needs sufficient fluid to operate effectively, ensuring smooth torque transfer. Inspect the fluid’s color and smell – dark or burnt fluid indicates contamination or overheating.

Check the fluid at recommended intervals, typically every 30,000 miles, or more frequently with heavy use. Maintaining proper fluid levels prevents premature wear and tear on internal components.

Visual Inspections for Leaks

Regularly inspect the manual transfer case for any signs of fluid leakage. Pay close attention to the seals around the input and output shafts, as well as the housing itself. A leak can compromise the positive displacement pump’s ability to maintain proper lubrication.

Look for drips or wet spots on the undercarriage. Even small leaks should be addressed promptly to prevent significant fluid loss and potential damage to internal gears and components.

Transfer Case Repair vs. Replacement

Deciding between repair and replacement of a manual transfer case depends on the extent of the damage. Minor issues, like seal replacements or simple gear adjustments, often favor repair, restoring functionality without significant cost.

However, extensive internal damage – cracked housings, severely worn gears, or failure of the positive displacement pump – usually justifies replacement. A new or rebuilt unit offers greater reliability and avoids potential recurring problems, ensuring continued optimal torque distribution.

Aftermarket Upgrades for Manual Transfer Cases

Enhancing a manual transfer case with aftermarket upgrades caters to specific needs. Gear ratio changes optimize performance for either increased crawling capability or highway efficiency, altering torque distribution.

Heavy-duty components, like reinforced shift forks and upgraded chain/splined shafts, bolster durability, especially crucial for vehicles subjected to demanding off-road conditions. These modifications improve reliability and withstand increased stress, ensuring consistent 4WD engagement.

Gear Ratio Changes

Altering gear ratios within a manual transfer case significantly impacts vehicle performance. Lower ratios, like those found in 4L, provide substantial torque multiplication for challenging terrain, enhancing crawling ability. Conversely, higher ratios optimize for highway cruising, improving fuel efficiency and reducing engine strain.

Selecting the appropriate ratio depends on intended use; off-road enthusiasts often favor lower ratios, while those prioritizing on-road driving benefit from higher ones. Careful consideration ensures optimal power delivery and vehicle control.

Heavy-Duty Components

Upgrading to heavy-duty components is crucial for manual transfer cases subjected to extreme stress, such as those in lifted vehicles or those frequently used for demanding off-road adventures. Reinforced gears, shafts, and housings withstand increased torque and impact forces.

These robust parts minimize the risk of failure, extending the transfer case’s lifespan and ensuring reliable performance. Investing in quality heavy-duty components provides peace of mind and prevents costly repairs or breakdowns during critical situations.

Transfer Case and Vehicle Compatibility

Ensuring proper transfer case compatibility with your specific vehicle is paramount for correct operation and avoiding damage. Factors like engine size, transmission type, and drivetrain configuration dictate the appropriate transfer case model.

Incorrect matching can lead to issues with gear ratios, shaft lengths, and mounting points, resulting in poor performance or even catastrophic failure. Always verify compatibility using manufacturer specifications or consult with a qualified mechanic before installation or replacement.

The Role of the Positive Displacement Fluid Pump

The positive displacement fluid pump is a critical component within the manual transfer case, responsible for maintaining consistent lubrication throughout the system. Unlike standard pumps, it delivers a fixed volume of fluid with each rotation, ensuring adequate pressure even at lower engine speeds.

This consistent flow channels fluid through strategically placed holes in the rear output shaft, lubricating gears and bearings, minimizing friction, and preventing premature wear. Proper pump function is vital for longevity.

Automatic vs. Manual Transfer Cases: Key Differences

Automatic transfer cases utilize sensors and actuators to engage four-wheel drive based on wheel slip, offering convenience but potentially delayed response. Manual transfer cases, conversely, require driver input for engagement, providing immediate control and a direct connection.

While automatic systems excel in all-weather adaptability, manual cases often preferred for off-road precision. Manual systems generally boast simpler designs and potentially greater durability, lacking the complexity of electronic controls.